flowShield

The flowShield is a UV-C light-based device designed to decontaminate sheath fluid and liquid waste in cell sorting processes. Using high-power UV-C LEDs in a flow-through reactor, it effectively inactivates a wide range of microorganisms, providing a reliable and energy-efficient method of preventing contamination without the need for labor-intensive chemical treatments or autoclaving.

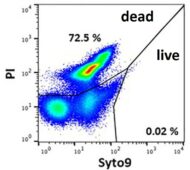

The decontamination efficiency of the flowShield has been tested and certified according to EN 13727 and EN 14476 (European standards for the evaluation of bactericidal and virucidal activity in the medical area):

- Validated bactericidal activity: ≥ 5.7 log10 reduction

- Validated virucidal activity: ≥ 5.4 log10 reduction

| Plug and play for most commercial cytometers | |

| Easy installation, maintenance free |

| Continuous logging and integrated self-test | |

| Acts on DNA via UV-C |

| Sheath: germ free cell sorting | |

| Waste: efficient and certified waste decontamination |

At a Glance

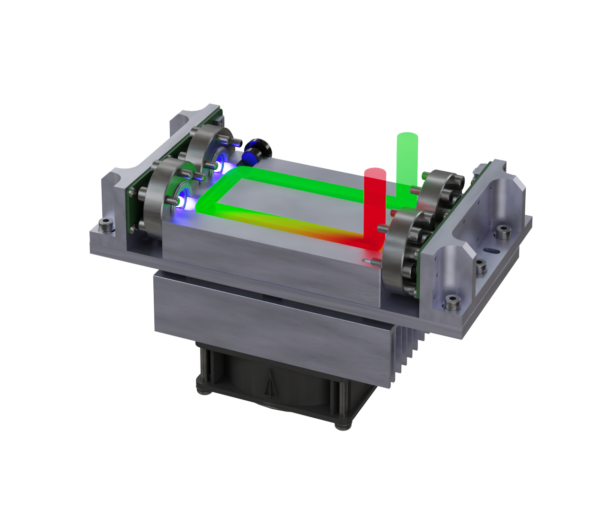

- UV-C dose up to 40 J/cm²

- Validated bactericidal activity: ≥ 5.7 log10 reduction

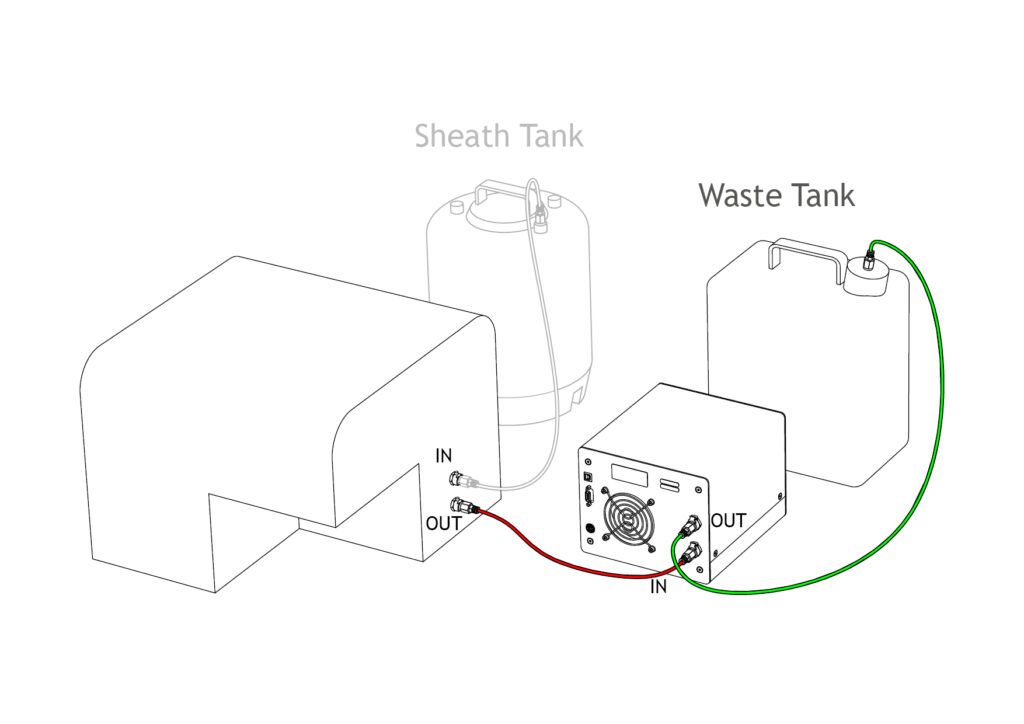

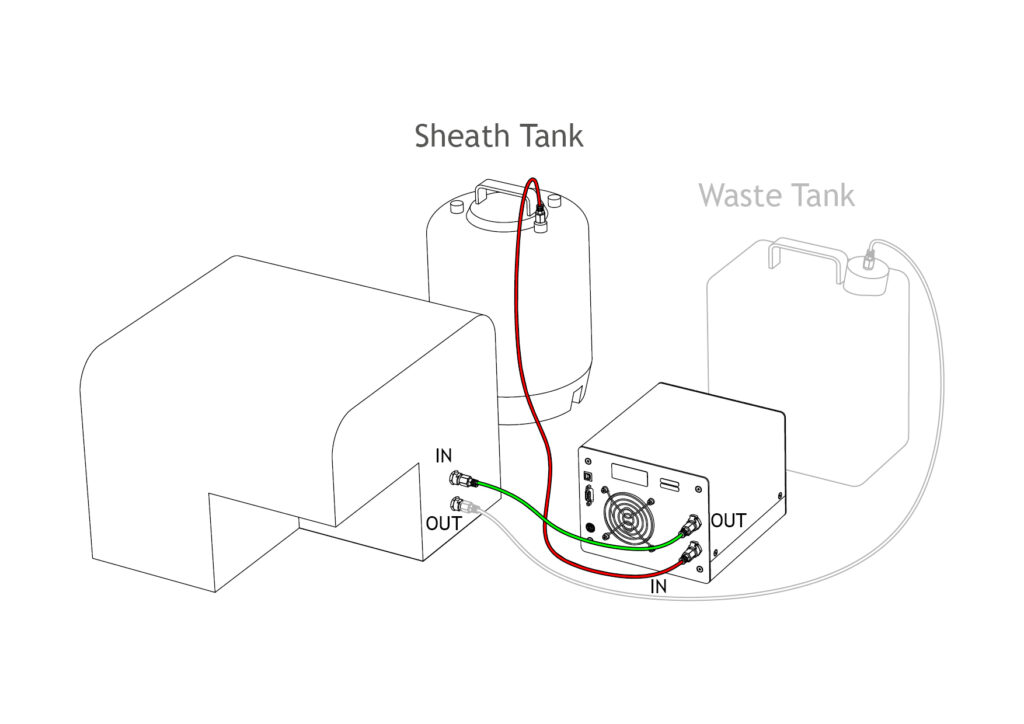

- Easy integration into the fluidic system via quick connectors

- Reliable stainless steel reactor including sheath fluid cooling

- Separate power supply and temperature controller

Introduction

Aseptic cell sorting provides the prerequisites for antibiotic-free cell cultivation after sorting. However, potential contamination of the cell sorting liquid by microorganisms such as bacteria, yeast, viruses and fungi can inhibit the cultivation of the sorted cells. Such contamination can happen, for example, when the sheath fluid reservoir is opened for refilling or through contamination by compressed air that is required for cell sorter operation. For this reason, decontamination is usually accomplished by regular flushing the fluidics with sodium hypochlorite or ethanol, which is a timeconsuming procedure and residues of cleaning reagents in the fluidics are toxic for the cells of interest.

UV-C Decontamination Mechanism

The lethal effect of UV-C light is well known for inactivating microorganisms without the side effects of a chemical treatment. The antimicrobial effect of UV-C light is based on the absorption of photons in the wavelength range of 200 – 280 nm by the DNA, resulting in the formation of pyrimidine dimers which inhibit DNA replication and consequently block transcription to RNA. This principle is used by the flowShield: UV-C emitting high-power LEDs are combined in a flow-through reactor to continuously irradiate the sheath fluid of a cell sorter or contaminated liquid waste. The resulting UV-C dose of four LEDs enables the reduction of P. aeruginosa by ≥ 5.7 log10.

Advantages

The flowShield effectively prevents the negative effects of germs on your cell culture. Using flow-through irradiation with UV-C LEDs to decontaminate the sheath fluid and liquid waste is an easy-to-use, robust, reliable and energy saving method.Conventional inactivation of contaminated liquid waste (autoclaving, chemical inactivation) is energy and labor intensive. Waste inactivated using flowShield is user friendly and guarantees that no harmful pathogens or genetically modified organisms (GMOs) enter the wastewater system or the surrounding ecosystem.

Have a look at our recent paper about „A UV-C LED-based unit for continuous decontamination of the sheath fluid in a flow-cytometric cell sorter”

Broschures

APE_flowShield_rev.4.0.0 (pdf / english)

Certificate of UV decontamination efficiency

APE_flowShield_certificate (pdf / english)

Publications (external)

A UV-C LED-based unit for continuous decontamination of the sheath fluid in a flow-cytometric cell sorter

Continuous UV-C Treatment for Safe Disposal of Pathogen Waste in Flow Cytometry

or

Email & Phone Contacts

APE has distributors around the world to give you the best support. Choose a country to find your local sales contact: