Dispersion Compensation & Pulse Compression

Dispersion Compensation Overview

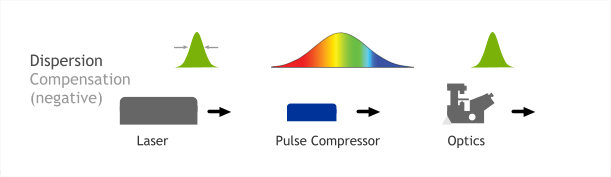

Dispersion compensation is the compensation of the fact that the speed of light in a given medium is depending on the wavelength. Especially laser pulses with short pulse durations in the ultrafast range. i.e. < 10 picoseconds (ps) are stretched by the dispersion of optical material when passing through optical components such as windows or lenses. Elaborate dispersion compensation by the means of pulse compression can compensate this effect. A pulse compressor is able to compensate negative as well as positive dispersion.

Group Velocity Dispersion

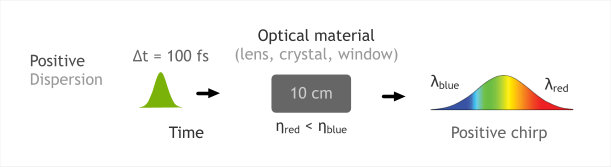

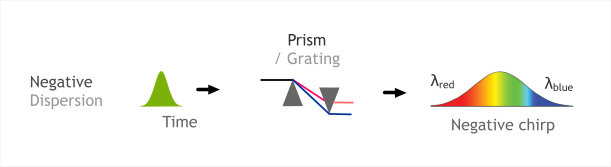

Dispersion describes the fact that the speed of light in a given medium is depending on the wavelength. The red wavelength parts propagate with higher speed of light in the material than the blue wavelength parts resulting in a time delay between the different wavelength parts. When the pulse leaves the medium this time delay (positive chirp) remains constant. A negative group velocity dispertion (GVD) is created by the angular dispersion of prisms or optical gratings.

Principle of Positive Dispersion

Principle of Negative Dispersion

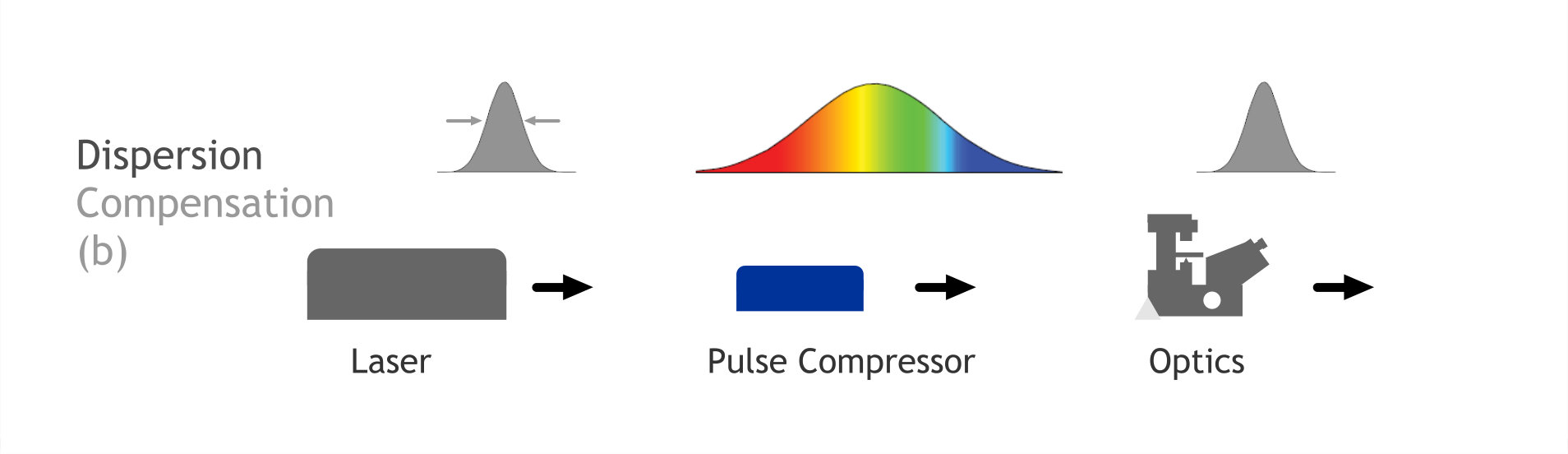

By compensating the positive dispersion with a corresponding negative dispersion the pulse is recompressed into the original input pulse duration.

Application

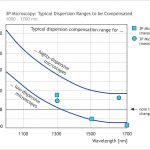

Dispersion compensation and pulse compression is essential whenever very short pulses are passing a lot of optical material, e.g. in a microscope for Multi-Photon-Excitation (MPE) microscopy. Positive GVD (Group Velocity Dispersion) in a MPE microscope of around 13 000 fs², for example, causes a broadening of a 100 fs pulse to 370 fs at 800 nm. The multi-photon absorption cross-section depends on the pulse width. High dispersion results in temporal broadening of the pulse, which distinctly interferes with the measurement conditions.

Dispersion compensation by pulse comression with motorized positioning of optical prisms generate a negative angular dispersion which then compensates the positive GVD of the MPE optics. Therefore, the pulse shows its original duration of 100 fs at the position of the specimen. The advantages of dispersion compensation for MPE microscopy are based on the fact, that the measuring signal – the fluorescence – becomes stronger with shorter pulses. Increased fluorescence improves the signal-noise-ratio. The life span of a probe depends on the average power applied on the probe when imaging. The average power needed to generate a corresponding number of fluorescence photons is lower with shorter pulses than with long ones. As a result the life span of the sample increases.

Principle of Negative Dispersion Compensation

Pulse Compression

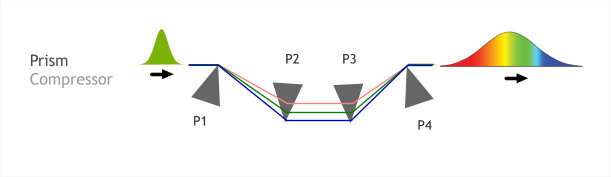

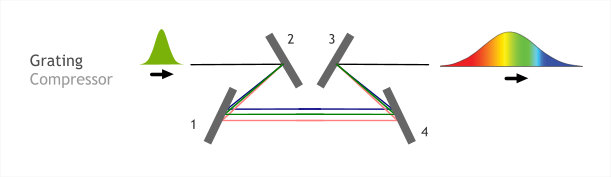

A pulse compressor for dispersion compensation is typically assembled by either two prism pairs or two grating pairs.

The prism compressor shows more versatility in its operation: it can be used for compensating a negative as well as a positive chirp whereas the grating compressor is only suitable for compensation of a positive chirp.

A prism compensator as typically used in microscopy is designed for pulse widths between 80 and 150 fs reaching a stretch of max. 700 fs. The amount of the angular dispersion generated by the prism pair, depends on the distance between the prisms and on the prism material: the wider the distance the higher the angular dispersion (for constant wavelength) and the higher the refractive index of the prism material the higher the angular dispersion. In order to get the highest possible angular dispersion in a device as compact as possible appropriate prism material need to be chosen.

Prism P1 splits up the polychromatic light of the laser pulse into the respective spectrum, so that the pulse spreads out in its spectral divergence. After the pulse has passed prism P2, it is still spectrally split up, but the wavelength parts propagate in parallel to each other. A setup of the prisms P3 and P4 symmetric to the prisms P2 and P1 makes sure that the spectral splitting of the beam is reversed.

Principle of a Prism Compressor

Fig. Dispersion compensation by pulse compression with a prism compressor: two prism pairs whose distance defines the amount of negative GVD. The length of the path inside the prisms generates positive GVD.

Principle of a Grating Compressor

Fig. Pulse compression with a grating compressor: two parallel grating pairs; only negative GVD is possible; the amount of GVD depends on the grating distance.

Negative dispersion is evoked by the different optical path length due to the respective wavelength. It is solely dependent on the distance between the two prisms. The path length in prism P2 is the crucial one for the difference in the optical path lengths. Moving the prisms at right angle to the beam direction changes the thickness of the material for all of the wavelengths at the same degree; it is as if a rectangular glass block has been inserted into the beam path. Thus, shifting the prisms changes the amount of positive dispersion.

In general, for dispersion compensation management the distance between the prisms should be variable as well as the length of beam path inside the prisms.

The amount of dispersion results from the fixed amount of negative dispersion plus the positive dispersion varying in accordance to the prism position. Thereby it is irrelevant, if prism P1 or prism P2 is moved. Maximum negative dispersion is achieved when both prisms are hit at the top, whereas maximum positive dispersion is achieved when both prisms are passed through close to the base. Thus, also a high degree of user-friendliness and beam pointing stability is guaranteed.